Future topics / Innovations - In the automotive sector

Innovative injection moulding technologies, increasing product and safety requirements, metal substitution with high performance plastics, miniaturisation and multi-parts components continue to be important product requirements in the entire plastic application domain of the automotive industry. The major topics in the future - even with respect to the increasing electrification in the car - will be electrically conductive, magnetic plastics or galvanically coated multi-part components as well as SMA actuators and assembly injection and SMA solutions in consumer and electronics.

With our technical know-how and production processes, we are equipped to secure the high requirements of design, optics and haptics. Particularly, in case of safety-relevant system components, our automated quality assurance measures, partially supported by the camera-equipped systems, will be of prime significance. APQP processes are applied as a standard in the tool production as well as in the injection moulding for the purpose of quality planning. We create the basis for highest precision and reproducibility by applying appropriate process and system validations, which we plan in close coordination with our customers in advance.

RKT Your System Vendor

Our company is competent in the entire value chain –starting from construction (mould making). We offer a wide range of services – right from feasibility analysis, FMEA, tool production with initial sample test report up to process installation and process validation as well as production, assembly of single parts and sub-assemblies as well as finishing.

Precision mould making - Tool production of the highest quality

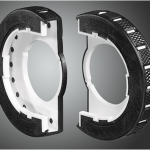

Our know-how that has developed from innumerable 2K/3K tools, tools with inserts, tools with complicated demoulding and experiences in the use of unusual plastics, is of crucial advantage for our customers. Increasingly shorter product development times do not leave any room for time-consuming iteration loops while searching for an optimal solution.

Our construction and mould making units work together with the customer on the corresponding offer-relevant data as soon as a customer request comes in, to be able to guarantee fast implementation in case of an order. Our focus hereby lies on the subsequent smooth injection moulding production. Our project management, tool production, manufacturing and assembly teams work across departments up to the transfer to the series production, whether in-house or at the customer site.

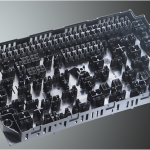

Production - Flexible and quick to respond

In addition to pure injection moulding, we can also execute product enhancements such as metallisation or painting with our external partners. We are equipped to print components with up to 6 colours or to label them using laser in-house. Moreover, we have years of experience in IMD (In-Mould decoration) and IML (In-Mould Labelling).

Our flawless documentation all along the production chain ensures that we generate quality as per the requirements of the automotive industry with respect to documentation, control and traceability.

Our objective is always a stable, reproducible production process that meets your requirements in accordance with reliable quality planning

Logistics / Planning - Competent and reliable

We enable time and cost optimised serial production at consistently high quality, which ensures a crucial competitive edge for our customers. Smooth workflow in the logistics area also plays an important role hereby. Our manufacturing devices are delivered worldwide with all the necessary documents.