Full-Service-Provider

Your project only needs one contact person – the RKT. We develop and implement a production process for you to manufacture your end product ready for sale. We plan a production line for you and are responsible for supporting the construction and commissioning of the system at RKT, including the manufacture and procurement of all necessary components of the finished product.

This includes design support for the plastic product (e.g. cartridge), mold construction, plastic injection moulding, the assembly of multiple components and the purchasing of all required materials such as biological components and primary and secondary packaging. We validate and produce your product in accordance with ISO standard 13485 or 15378 (primary packaging for the pharmaceutical industry) and provide you with all validation documents in German or English.

Partner for innovative Start-ups

RKT is committed to being a manufacturing partner for entire assemblies in microfluidics and has developed its own strategy to work with start-ups to enable the industrialization of microfluidics.

By using its advanced plastics technology, RKT has successfully developed into a specialist in the field of fluidics (nano- and microfluidics, MEMS).

Biotechnology and medical markets build on innovations from the last two decades and make new and innovative products commercially available. Certain areas such as in vitro diagnostics, cell analysis, liquid biopsy, next-generation sequencing and proteomics have started to establish themselves in the field of laboratory and point-of-care diagnostics. With our extensive start-up experience, we work on new products of tomorrow, often in close cooperation with well-known research institutions and their spin-offs. RKT is an incubator in the truest sense of the word.

In contrast to large corporations, start-ups often do not have experienced product development teams and knowledge of the industrial implementation of the product idea in scalable production processes. This is where RKT comes in. In a holistic approach, the subsequent series production is taken into account right from the start of the project - this means that the quality department and process development are closely involved right from the start and accompany the product development process. Necessary investments and the cost structure of the end product are also taken into account.

We work hand in hand with our sister company and innovation hub ASG (Actuator Solutions GmbH) to develop solutions for microfluidic applications in the field of device construction for molecular diagnostics, sequencing and cell observation. The task also includes optical systems in connection with micro-actuators.

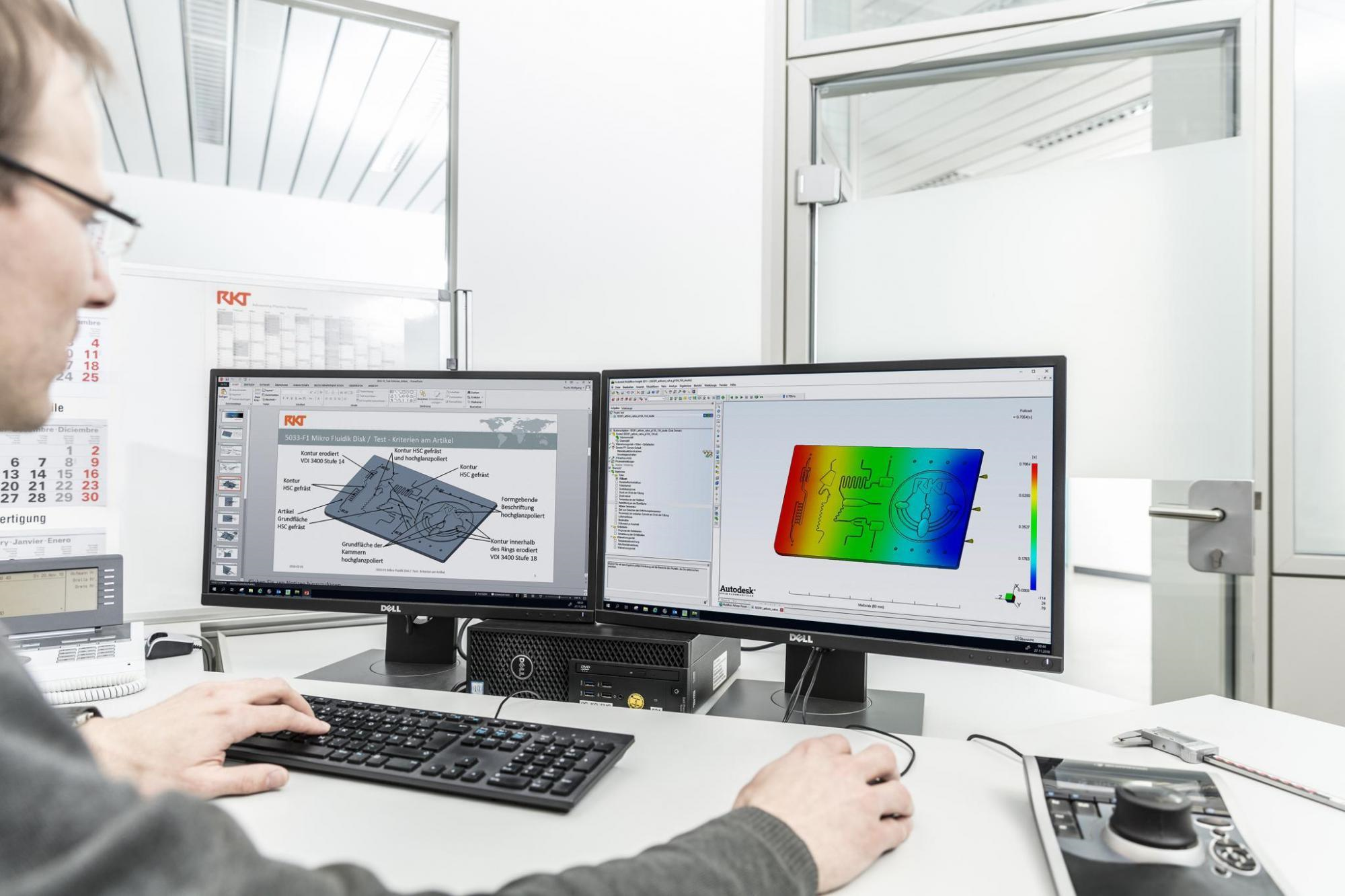

Product Development and DfM (Design for Manufacturing)

We support you right from the concept phase with the know-how of our developers and engineers. The goal is a technically mature component that is individually designed for your application and can be stably produced in series. This may require adjustments to the geometry and tolerances, and possibly even a change in the planned plastic.

Among other things, the production and further processing process (marking, installation of several components, sterilization methods) as well as application-relevant requirements such as temperature resistance are taken into account. Already in this phase, the quality department provides support in the form of advance quality planning, especially with regard to the drawing design, the measurement strategy in series production and the design FMEA.

Tool Design and Tool Construction

We set the course for series production as early as the tool design stage. This begins with the number of cavities (cavities) and the general design of the mold (hot runner, injection point, ejector), supported by filling simulations.

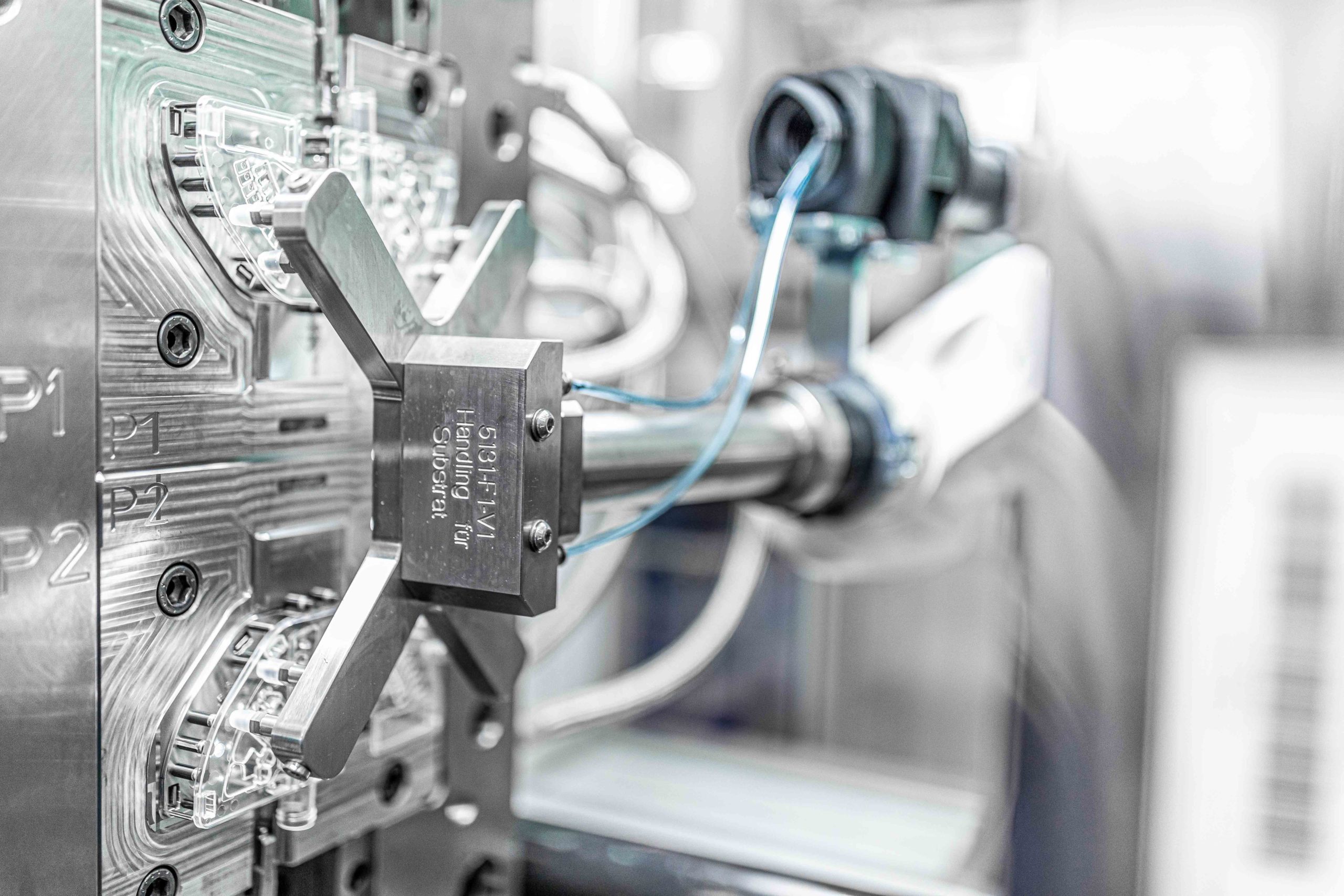

Toolmaking

We can look back on half a century of experience in the construction of injection molds for a wide variety of applications, from which we continue to draw. We rely on traditional metalworking as well as ultra-modern manufacturing processes such as lasing and LIGA. Our tools are designed for stable production processes and a long service life. We also maintain the tools we use in injection molding and closely monitor the performance of these tools - always combined with a preventive maintenance concept in order to minimize rejects and maximize the service life of the tool as well as to optimize costs.

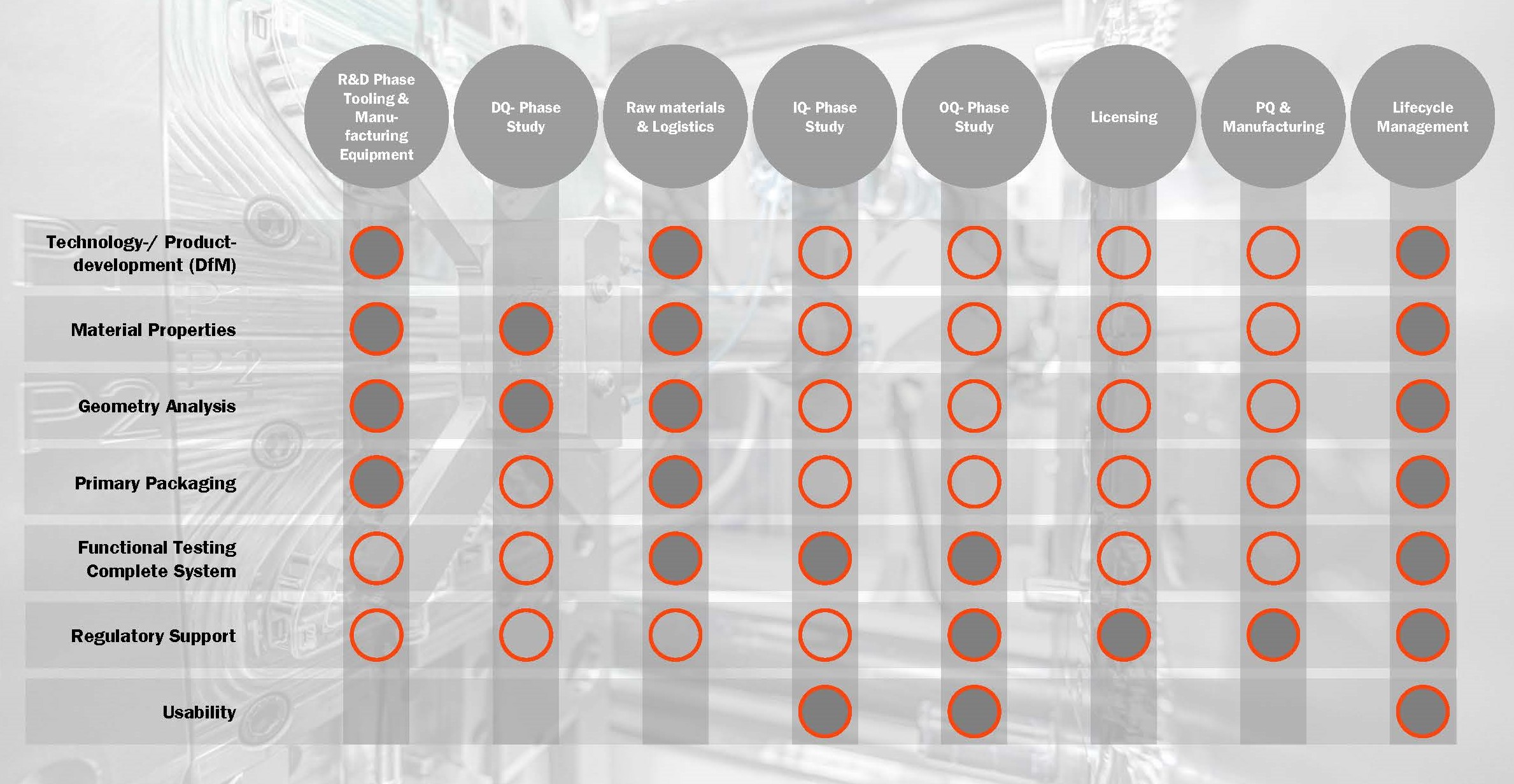

Tool Validation

We validate the tools for you according to your specifications. The standard is validation 13485 (DQ,IQ,OQ,PQ), but validations according to PPAP and other standards are also possible. Other services such as DOE or Pro-Op and filling studies are standard. In addition, CT scans or polariscopic analyzes can be performed.

Serial Production in Plastic Injection Moulding

We process all thermoplastics, including all common functional additives (electrically conductive, increasing mechanical stability) on injection moulding machines from 40 to 250 tons locking force, in 1K, 2K, 3K processes in gray rooms and in ISO 8 and ISO 7 clean rooms, if desired also analyte-free (free of foreign DNA).

We remove the plastic products cavity-clean using removal robots and plan appropriate storage systems in order to achieve high production autonomy with low reject rates - where possible we try to implement camera inspection systems.

Process Development

The production process is already laid out in the design phase as part of the DfM (Design for Manufacturing). Here, the process development team works both on the injection moulding process of the plastic product and on the design of the production process for further processing (filling, assembly, packaging). In particular, the flow of goods in production (raw materials, semi-finished and finished products), but also the logistics of the finished product itself and requirements are already taken into account and planned in this phase (e.g. a temperature-controlled logistics chain). The quality department is an integral part of the specific project teams and advises both external customers and internal project members.

Contact

Stephan Schulak

Geschäftsführer

Managing Director

Tel.: +49 9461 954-0

Fax: +49 9461 954-110

Markus Kamm

VP Vertrieb, Projekte & SCM

VP Sales, Project & SCM

Tel.: +49 9461 954-120

Fax: +49 9461 954-180

RKT GmbH

Tel.: +49 9461 954-0

Fax: +49 9461 954-110

Contact us